What is bin picking?

Random or automated bin picking is used at the input stage of manufacturing, often in automotive, white goods, or machine tending. A robot empties a bin of bulk parts into a machine, feeder, or conveyor for further processing. Bin-picking usually involves one type of part and requires precise object placement for tasks like stamping or measurement. A suitable 3D vision system is critical, as it affects the robot’s ability to detect, pick, and place parts accurately.

3D vision in bin picking

Improved Object Recognition

With high-resolution, ultra-precise native 3D point clouds, the robot can enhance object recognition and detect a greater number of parts.

Reliable 3D Picking Accuracy

3D vision enables reliable object boundary detection by accurately capturing object's size, orientation, and absolute position.

Correct Placement and Orientation

Vision-guided robots can perform precise pick-and-place tasks, ensuring accurate placement and orientation while avoiding collisions and damage.

Why use a Zivid camera?

See tiny and detailed objects, densely stacked or randomly arranged.

Zivid provides high resolution and precision point clouds with minimal occlusion, capturing a variety of shapes and sizes with all the fine details.

- High accuracy for precise pick and place

- Infield correction that allows you to verify dimension trueness of your camera any place, any time

- Hand-eye calibration Zivid handles the math so that our customer just needs to provide the dataset.

-1.png?width=1200&length=1200&name=Contrast%20Distortion%20before%20vs.%20after%20(1)-1.png)

See shiny, reflective, machined, and polished parts

3D HDR and Artifact Reduction Technology (ART) ensure excellent suppression of imaging artifacts caused by reflections, inter-reflections, specular highlights, and high-contrast transitions.

ART is Zivid’s unique set of sophisticated tools and filters designed to help you handle challenging objects, often including highly reflective and shiny parts.

Achieve Consistent Results in Real Production Environments

One of the main challenges with vision systems is obtaining reliable data from sensors. Output can often vary based on scene lighting and color temperature.

With a single camera setting, you can consistently capture robust 2D images and point cloud data, even under changing ambient light conditions. Maintain high picking accuracy despite variations in temperature and lighting intensity.

Maintaining the Current System

❌ The robot has difficulty handling a wide variety of objects, especially small items like tiny screws.

❌ The vision system struggles to capture highly reflective or dark materials due to imaging artifacts.

❌ The robot has trouble identifying accurate picking points because of the random placement of parts.

❌ The vision camera is not designed for robot-mounted use.

❌ It lacks industrial-grade robustness and is sensitive to changes in ambient lighting conditions.

With Zivid Camera

✅ The robot can see tiny and detailed objects with high accuracy.

✅ The vision system can handle challenging objects, often including highly reflective and shiny parts.

✅ The robot can recognize a very complex-shaped part for successful pick and place.

✅ The vision camera is suitable for robot-mounting, increasing total flexibility of capture position.

✅ Delivers ultra-stable output with near-total immunity to ambient light.

Customer Stories

ING Robotics' all-in-one 3D vision solution for manufacturing

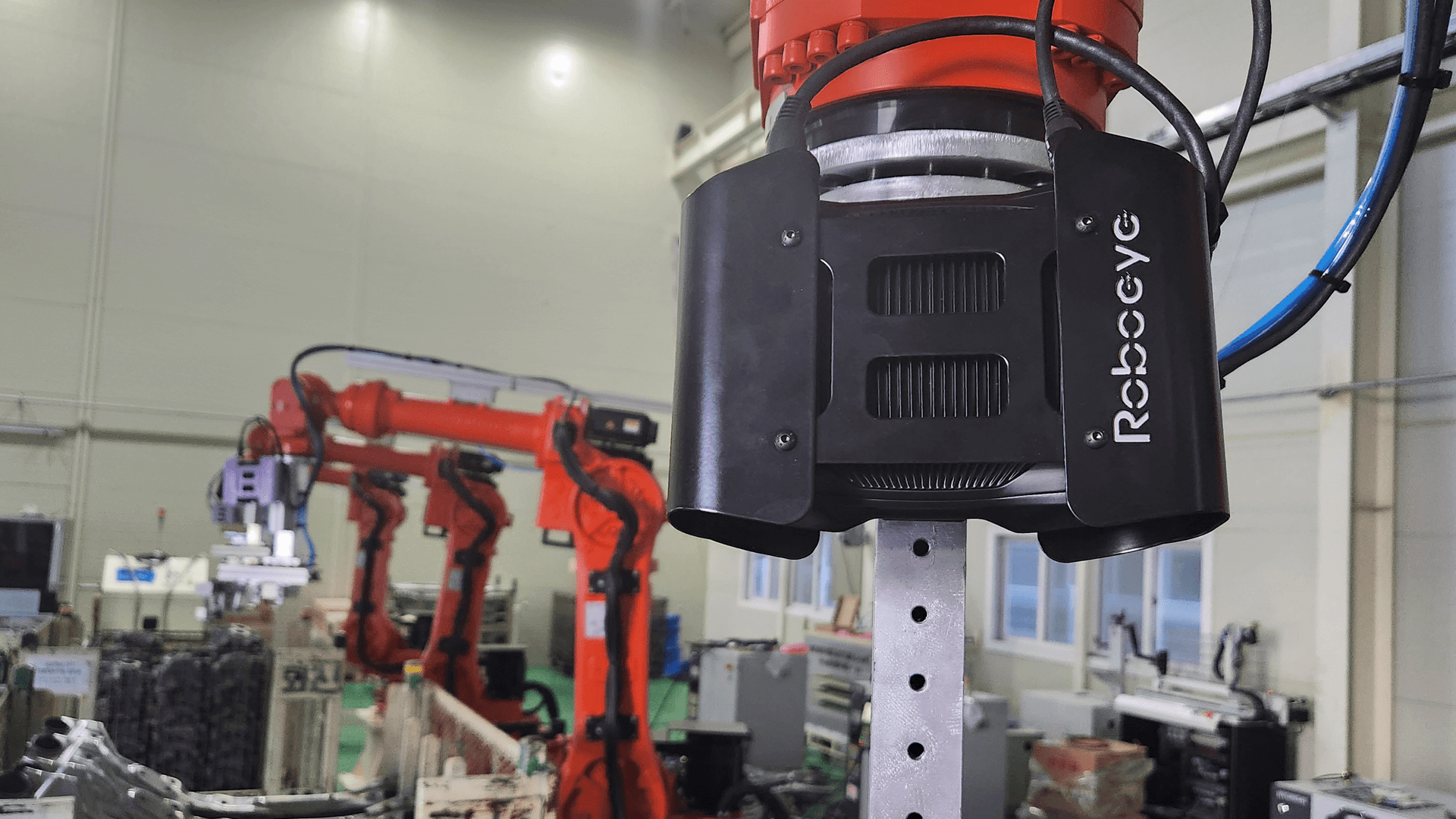

ING Robotics introduced ROBOEYE, a 3D vision solution combining the Zivid 2+ L110 3D for precision assembly automation

-2-2.webp?width=1144&height=640&name=Untitled%20(1144%20%C3%97%20614px)-2-2.webp)

Innodura's complex parts hanging solution for assembly lines

Hanging parts for processing is a task that has been primarily carried out manually, and automating it has proven to be a real challenge.

-1.webp?width=1920&height=1080&name=Scenario%20Automated%20Assembly%20with%20Zivid%20Two%203D%20camera%20-%20White%20Goods%20(1)-1.webp)

Plaif's appliance manufacturing solution

Plaif has leveraged advances in AI and 3D machine vision to bring a high-reliability solution in appliance manufacturing.